Frontloading machines

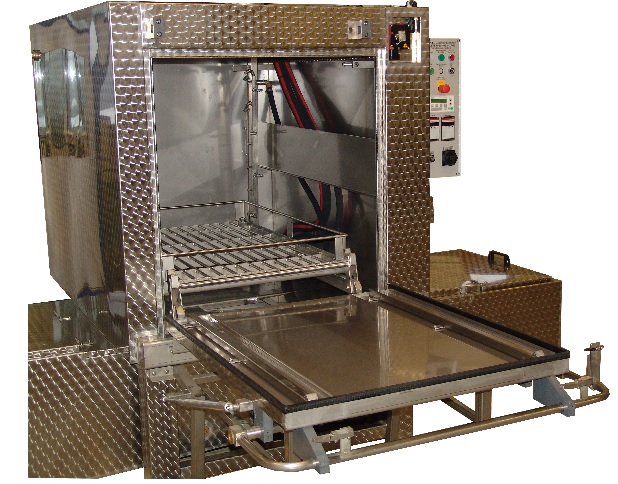

Our Frontloading machines, also named one chamber cleaning machines, are solid machines made from stainless steel that clean with spraying technology.

In this type of machine, the parts rest inside the fix washing basket while a motorized, circumferential nozzle system moves along the washing basket. For an excellent cleaning result, the lateral nozzles are always aligned in the direction of the movement. The nozzle system in stainless steel is supplied by two powerful pumps made from stainless steel.

Our Frontloaders are available in the following versions:

- For the use with alkaline, aqueous cleaning agents (type FL-L)

- In a 2-tank-version - integration of 2 cleaning processes in one machine e.g. washing and rinsing (type FL-2-tanks)

Ergänzendes

Product

To minimize the costs for heating and energy, our frontloaders are completely insulated. The circulating medium is filtered entirely in the backflow by a filter box made from stainless steel.

Furthermore, these machines are equipped with powerful pumps made from stainless steel, a programmable controller and a digital temperature indicator. A protection from dry-running protects the pumps and the heater. The integrated leakage monitoring system shuts down the machine in the case of a leakage.

Application

- Service and maintenance

- Ideal for big and heavy parts

- Usable for delicate parts (due to the resting position of the work pieces)

Mode of operation

In our Frontloading machines, the parts rest in the fix washing basket while the circumferential nozzle system moves along the washing basket.

The pumps with pump heads in stainless steel bring the medium from the insulated tank to the motorized nozzle system. The nozzles of the nozzle system are always aligned in the direction of the movement and rest during a while in each end position to optimize the cleaning result.

The medium circulates inside the machine and passes through a full flow filtration. The filter basket can be taken out easily for cleaning purpose.

The temperature is indicated digitally and is steplessly variable. The frontloaders are equipped with a programmable controller with a control panel, a digital temperature controller and a fault indication.

Technical Data

| FL 8/8 | FL 8/12 | FL 10/15 | FL 20/12 | |

|---|---|---|---|---|

| Rated input voltage | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz |

| Flowrate of the pumps | 4,5 - 12 m³/h 3,68 kW | 2 pumps à 4,5 - 12 m³/h 3,68 kW | 2 pumps à 4,5 - 12 m³/h 3,68 kW | 2 pumps à 4,5 - 12 m³/h 3,68 kW |

| Max. operating pressure | 4,4 - 6,1 bar | 4,4 - 6,1 bar | 4,4 - 6,1 bar | 4,4 - 6,1 bar |

| Operating temperature - standard | 62°C | 62°C | 62°C | 62°C |

| Operating temperature - optional | 75°C | 75°C | 75°C | 75°C |

| Usable width | 800 mm | 800 mm | 1000 mm | 2000 mm |

| Usable depth | 800 mm | 1200 mm | 1500 mm | 1200 mm |

| Usable height | 800 mm | 800 mm | 900 mm | 900 mm |

| External dimensions (WxDxH) | 2000 x 1300 x 2100 mm Depth with opened door: 2350 mm | 2170 x 2480 x 2100 mm Depth with opened door: 2750 mm | 2300 x 2800 x 2180 mm Depth with opened door: 3150 mm | 3230 x 2620 x 2180 mm Depth with opened door: 4000 mm |

| Heating | 2 x 7,5 kW | 2 x 7,5 kW | 2 x 7,5 kW | 2 x 7,5 kW |

| Max. loading capacity | 1000 kg | 1000 kg | 1000 kg | 1000 kg |

| Max. tank volume | 450 l | 450 l | 450 l | 450 l |

| On-time | 70 % | 70 % | 70 % | 70 % |

Standard equipment

- Conceived for alkaline aqueous cleaning agents with a pH value of 7-12

- The machine is completely made from stainless steel

- Solid washing machine made from stainless steel

- Moveable circumferential nozzle system

- Complete heat insulation for little energy consumption

- Full flow filtration with a stainless stell filter box (200 μm)

- Programmable controller Siemens with adjustable parameters ans control panel including indication of perturbations

- Solid, moveable washing basket in stainless steel

- Powerful horizontal pumps with pump heads in stainless steel and high quality seals

- Tubular electric heating cartridges

- Leakage control system with safety shutdown

- Machine with fold door and electromechanical safety positioning switch that locks the door during the process of washing and dripping

- Digital temperature indication

- Aslope tank bottom for easy cleanout

- Level control system with protection against dry-running and safety shutdown

- Connection for exhaustion

Optional equipment

The following options are available:

- Increase of temperature from 62°C up to 75°C

- Automatic level control

- Automatic chemical dosage

- Oil separator

- Exhaustion

- Vapour condenser

- Blowing

- Lift door

- Additional filtration

- Automatic insertion of the washing basket

- Rinsing lances for manual cleaning (high and low pressure)

- Transport trolley

- Cleaning agent

Further options on demand.

Product

Our frontloading machines in the solvent version are not insulated and not heated. Beyond these, this version is identic to the heated frontloading machines . They are equipped with full-flow filtration, stainless stell pumps and a SPS-controller. They dispose of the Parts Clean Control, too, that indicates the actual temperature. You will find further information in the Standard equipment.

Application

- Service and maintenance

- Ideal for big and heavy parts

- Usable for delicate parts (due to the resting position of the work pieces)

Mode of operation

In our Frontloading machines, the parts rest in the fix washing basket while the circumferential nozzle system moves along the washing basket.

The pumps with pump heads in stainless steel bring the medium from the insulated tank to the motorized nozzle system. The nozzles of the nozzle system are always aligned in the direction of the movement and rest during a while in each end position to optimize the cleaning result.

The medium circulates inside the machine and passes through a full flow filtration. The filter basket can be taken out easily for cleaning purpose.

The temperature is indicated digitally. The frontloaders are equipped with a programmable controller with a control panel and a fault indication.

Technical Data

| FL-K 8/8 | FL-K 8/12 | FL-K 10/15 | FL-K 20/12 | |

|---|---|---|---|---|

| Nominal input voltage | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz |

| Flow rate of the pump | ||||

| Operating pressure max. | < 0,7 bar | < 0,7 bar | < 0,7 bar | < 0,7 bar |

| Operating temperature max. | 35°C | 35°C | 35°C | 35°C |

| Usable width | 800 mm | 800 mm | 1000 mm | 2000 mm |

| Usable depth | 800 mm | 1200 mm | 1500 mm | 1200 mm |

| Usable height | 800 mm | 800 mm | 900 mm | 900 mm |

| External dimensions (WxDxH) | 2000 x 1300 x 2100 mm Depth with opened fold door: 2350 mm | 2170 x 2480 x 2100 mm Depth with opened fold door: 2750 mm | 2300 x 2800 x 2180 mm Depth with opened fold door: 3150 mm | 3230 x 2620 x 2180 mm Depth with opened fold door: 4000 mm |

| Loading capacity max. | 1000 kg | 1000 kg | 1000 kg | 1000 kg |

| Tank volume max. | 450 l | 450 l | 450 l | 450 l |

| Heating | - | - | - | - |

| On-time | 70 % | 70 % | 70 % | 70 % |

Standard equipment

- Conceived for solvent-based cleaning agents with a flashpoint above 55°C

- Machine completely in stainless steel

- Solid washing pan in stainless steel

- Moveable and circumferential nozzle system

- Full flow filtration with a removable filter box made from stainless steel (200 μm)

- Programmable controller Siemens with adjustable parameters incl. fault indication

- Moveable, solid washing basket made from stainless steel

- Horizontal pumps with a stainless steel pump head and high quality seals

- Leakage monitoring control with safety shutdown

- Machine equipped with a fold door and an electromechanical safety positioning switch that locks the machine during the cleaning and the dripping process

- Digital temperature indication

- Aslope tank bottom for easy cleanout

- Level control system with safety shutdown to protect the pumps from dry-running

- Connection for an exhaustion

Optional equipment

The following options are available:

- Exhaustion

- Blowing

- Lift door

- Additional filtration

- Automatic insertion of the washing basket

- Transport trolley

- Cleaning agent

Further options on demand.

Product

Our frontloading machines with 2 tanks are based on the standard Frontloaders. Construction and equipment correspond to the one-tank machine, but a second process (rinsing) has been integrated into the system.

The medium circulates and is filtered in full-flow. The seesaw system brings each medium back into it's tank. Both tanks are fully insulated and heated.

The washing and the rinsing process are programmable at the controller. The temperature is indicated digitally.

Application

- Service and maintenance

- Ideal for big and heavy parts

- Usable for delicate parts (due to the resting position of the work pieces)

Mode of operation

In the frontloading machine FL 2-tanks, both processes washing and rinsing are carried out by spraying.

Two separate nozzle systems in stainless steel are supplied from the respectif insulated and heated medium tank. The parts lay in the washing basket while the circumferential, motorized nozzle system moves along the washing basket.

In the machines with 2 tanks, an integrated seesaw-system brings each medium back into the respective tank. Both medium circulate in the machine. A level control system protects the pomps and the heaters in each tank from dry-running.

The machine is standardly equipped with a fold door, that serves as platform for loading and unloading. A lift door is optionally available.

Technical Data

| FL 8/8 2-tanks | FL 8/12 2-tanks | FL 10/15 2-tanks | FL 20/12 2-tanks | |

|---|---|---|---|---|

| Rated input voltage | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz | 3x400 VAC+N+PE / 50 Hz |

| Usable width | 800 mm | 800 mm | 1000 mm | 2000 mm |

| Usable depth | 800 mm | 1200 mm | 1500 mm | 1200 mm |

| Usable height | 800 mm | 800 mm | 900 mm | 900 mm |

| External dimensions (WxDxH) | 2800 x 1300 x 2100 mm Depth with opened fold door: 2350 mm | 2800 x 1700 x 2100 mm Depth with opened fold door: 2750 mm | 2800 x 2000 x 2200 mm Depth with opened fold door: 3150 mm | 3600 x 2900 x 2200 mm Depth with opened fold door: 4000 mm |

| Operating temperature - standard | 62°C | 62°C | 62°C | 62°C |

| Operating temperature - optional | 75°C | 75°C | 75°C | 75°C |

| Max. loading capacity | 1000 kg | 1000 kg | 1000 kg | 1000 kg |

| On-time | 70 % | 70 % | 70 % | 70 % |

| Washing process | ||||

| Flow rate of the pump | 4,5 - 12 m³/h 3,68 kW | 2 pumps à 4,5 - 12 m³/h 2x3,68 KW | 2 pumps à 4,5 - 12 m³/h 2x3,68 kW | 2 pumps à 4,5 - 12 m³/h 2x3,68 kW |

| Max. operating pressure | 4,4 - 6,1 bar | 4,4 - 6,1 bar | 4,4 - 6,1 bar | 4,4 - 6,1 bar |

| Max. tank volume | 330 l | 330 l | 330 l | 330 l |

| Heating | 2 x 7,5 kW | 2 x 7,5 kW | 2 x 7,5 kW | 2 x 7,5 kW |

| Rinsing process | ||||

| Flowrate of the pump | 7 - 18 m³/h 1,5 kW | 7 - 18 m³/h 1,5 kW | 7 - 18 m³/h 1,5 kW | 7 - 18 m³/h 1,5 kW |

| Max. operating pressure | 2,2 - 2,8 bar | 2,2 - 2,8 bar | 2,2 - 2,8 bar | 2,2 - 2,8 bar |

| Max. tank volume | 250 l | 250 l | 250 l | 205 l |

| Heating | 6 kW | 6 kW | 6 kW | 6 kW |

Standard equipment

- Conceived for alkaline aqueous cleaning agents with a pH value of 7-12

- The machine is completely made from stainless steel

- Solid washing pan made from stainless steel

- Moveable circumferential nozzle system

- Complete heat insulation for little energy consumption

- Solid, moveable washing basket in stainless steel

- Powerful horizontal pumps with pump heads in stainless steel and high quality seals

- Seesaw-system - the mediums from the washing and from the rinsing tank circulate separately inside the machine

- Tubular electric heating cartridges

- Leakage control system with safety shutdown

- Machine with fold door and electromechanical safety positioning switch that locks the door during the process of washing and dripping

- Digital temperature indication "Parts Clean Control"

- Level control system with protection against dry-running and safety shutdown

- Connection for exhaustion

- Programmable controller Siemens with adjustable parameters ans control panel including indication of perturbations

- Full flow filtration with a stainless stell filter box (200 μm)

- Aslope tank bottom for easy cleanout

- 2 separate cleaning processes "washing" and "rinsing" in the same machine - with 2 tanks

Optional equipment

The following options are available:

- Increase of temperature from 62°C up to 75°C

- Automatic level control

- Automatic chemical dosage

- Oil separator

- Exhaustion

- Vapour condenser

- Blowing

- Lift door

- Additional filtration

- Automatic insertion of the washing basket

- Rinsing lances for manual cleaning (high and low pressure)

- Transport trolley

- Cleaning agent

Further options on demand.